A Practical Guide for European & American B2B Buyers

Choosing the right lingerie OEM manufacturer is one of the most critical decisions for brands, wholesalers, retailers, and private-label businesses. A reliable China lingerie OEM factory directly impacts product quality, delivery timelines, compliance, and your brand’s reputation in competitive EU and US markets.

For buyers sourcing bra OEM manufacturing, underwear OEM supply, seamless lingerie production, or private label lingerie, understanding how to properly evaluate a factory can significantly reduce risk and improve long-term profitability. Below are the 7 key criteria every B2B buyer should consider—along with how choosing the wrong OEM partner can hurt your business.

1. Lingerie-Focused Manufacturing Experience

Lingerie is not general apparel. It requires precise pattern-making, fabric control, stretch management, and sizing accuracy. A reliable factory should specialize specifically in lingerie categories such as bras, underwear, shapewear, and seamless products.

Risk of choosing the wrong OEM: inconsistent fit, sizing complaints, and high return rates.

2. OEM & ODM Capability

International buyers often need both OEM and ODM services. OEM supports your custom designs, while ODM allows you to customize ready-developed styles to speed up market entry.

Risk of choosing the wrong OEM: long development cycles, high sampling costs, and missed selling seasons.

3. Product Development & Sampling Speed

A professional lingerie OEM factory should offer fast sampling, accurate pattern adjustments, and smooth communication during development. Speed-to-market is a major competitive advantage for B2B buyers.

Risk of choosing the wrong OEM: repeated sampling delays and rising development costs.

4. Quality Control System

Reliable factories implement quality control at every stage—fabric inspection, in-line production checks, and final inspection before packing. Consistent quality is essential for repeat orders.

Risk of choosing the wrong OEM: unstable quality, customer complaints, and brand damage.

5. Compliance & Certifications

For EU and US markets, compliance is non-negotiable. A qualified lingerie OEM manufacturer should meet standards such as BSCI, OEKO-TEX®, ISO9001, SMETA, GRS, and GOTS.

Risk of choosing the wrong OEM: failed audits, blocked shipments, and lost retail opportunities.

6. MOQ Flexibility & Production Capacity

Flexible MOQ allows buyers to test the market before scaling. At the same time, the factory must be capable of handling bulk orders with stable lead times.

Risk of choosing the wrong OEM: forced high MOQs or inability to scale successful products.

7. Communication & Delivery Reliability

Clear English communication, transparent timelines, and on-time delivery are critical when working with overseas manufacturers.

Risk of choosing the wrong OEM: misunderstandings, delayed shipments, and missed selling seasons.

How Chuangrong Solves These Challenges

Shantou City Chuangrong Apparel Industrial Co., Ltd. is a professional lingerie OEM/ODM manufacturer in China, established in 2012 and located in Gurao Town, Shantou—the core hub of lingerie production.

Why B2B Buyers Choose Chuangrong:

* 20,000㎡ self-owned factory with 510 skilled workers

* Strong focus on seamless lingerie, menstrual underwear, shapewear, and sexy lingerie

* OEM & ODM services to support both custom designs and fast launches

* Sample MOQ: 1 piece | Bulk MOQ: 3,000 pcs per style per color

* Stable 35-day delivery after pre-production sample approval

* Certified with BSCI, OEKO-TEX® Standard 100, ISO9001, GRS, GOTS, and SMETA

* Trusted OEM partner for global brands such as ALDI, LIDL, INDITEX, AUCHAN, BOUX, NINE WEST, and SHEIN

* Multiple stable production lines and an in-house testing laboratory ensuring quality consistency

Chuangrong is positioned in the mid-to-high-end lingerie market, offering competitive pricing without compromising quality or compliance.

Take Action: Start a Low-Risk Trial Order with Chuangrong

Choosing the right lingerie OEM factory is about minimizing risk and maximizing long-term value. With flexible MOQ, certified quality, fast development, and proven export experience, Chuangrong Apparel helps B2B buyers source lingerie with confidence.

Partner with Chuangrong and start your low-risk trial order today!

📩 Email: Lexie@Sharicca.com

🌐 Website: www.chuangrongapparel.com

- 1.2mm Micro Fiber Material1

- 100% cotton fabrics1

- 100ml glass bottle1

- 100ml slanted shoulder bottle1

- 15.6 Inch Waterproof Laptop Bag1

- 15ml Glass Dropper Bottles1

- 17.3 Inch Large Capacity Laptop Bag1

- 1981 Clothing Combat Uniform1

- 2023 Wholesale Women Handbag1

- 2025 Cosmetic Tube1

- 3 layer ski jacket1

- 3-Piece Can1

- 3-layer jacket with a MERINO wool1

- 3-pc aerosol can1

- 30ml airless plastic bottle1

- 30ml cosmetic glass bottles1

- 30ml essences oil bottle1

- 30ml essences oil dropper bottle1

- 30ml oil bottle glass1

- 35%Cotton 65%Polyester Cap1

- 3x5 plastic bags1

- 4 Season Hat1

- 4.0 Inch IPS Touchscreen1

- 50g crystal jars1

- 50ml airless plastic bottle2

- A backpack with laptop compartment1

- Acrylic Nail Drills1

- Adhesive Anti mould Sticker1

- Adjustable Plastic Buckle1

- Advantages of tin can1

- Adventure Waterproof Roll Top Backpack Supplier1

- Adventure backpacks for college1

- Aerosol Can5

- Aerosol Cans2

- Aerosol Spray Can1

- Aerosol Spray Tin Can1

- Aerosol Tin Can1

- Aerosol Tinplate Cans1

- Aerosol can factory1

- Aerosol cans1

- Aerosol tin Cans1

- Affordable Bean Bag Chair1

- Affordable Bean Bag Chairs1

- Affordable EVA cases for tool storage1

- Affordable Living Room Furniture1

- Affordable bulk period panties for wholesalers1

- Air Quality Monitoring1

- Airless Pump Bottles1

- All-season Water-repellent Mid Lace-up Hiking Boots1

- Aluminum Venetian Blinds1

- Aluminum Vertical Blinds1

- Amber Glass Dropper Bottles1

- Amber Glass Pump Bottles1

- Amber glass bottle1

- Ankle Heel Support Anti-Fatigue Hiking Boots1

- Ankle Support Anti-fatigue Walking Working Shoes1

- Anti Infrared Resistant Functional Camouflage Fabric1

- Anti Slip Working Shoes1

- Anti mildew pack1

- Anti mildew paper1

- Anti mildew sheets1

- Anti mold Packet1

- Anti-Shock EVA Hard Case1

- Anti-Slip Table Tennis Shoes1

- Anti-Tamper Radiator Valve1

- Anti-Theft Thermostatic Radiator Valve1

- B2B Lingerie Factory Cooperation1

- B2B customized seamless bra for mobility-limited women1

- B2B premium underwear Manufacturer1

- B2B tailored front-hook bra for mobility-limited women1

- BMX Champion women1

- BMX MTB Teamwear1

- BMX team wear customed1

- BMX wear1

- BMX wear customed factory1

- Baby Products1

- Bag manufacturers in china1

- Ballistic Hoodie1

- Bathroom Mirror with Lights1

- Bean Bag Armchair1

- Bean Bag Beans1

- Bean Bag Couch1

- Bean Bag Factory2

- Bean Bag Filling Material2

- Bean Bag For Sitting1

- Bean Bag Manufactory1

- Bean Bag Refill Beans2

- Bean Bag Shape2

- Bean Bag Sitting Posture1

- Bean Bag Sofa2

- Bean Bag Supplier2

- Bean Bag Vhairs for Kids1

- Bean Bag Wholesale1

- Bean Bags for Kids1

- Beijing Local Travel Agency2

- Beijing Tours Guide1

- Beijing Travel Agency2

- Beijing attractions1

- Beijing private tour package1

- Bespoke Lightweight Waterproof Gym Bag Factory3

- Best shoulder bag brands1

- Big Vanity Mirror with Lights1

- Bio-Based Leather2

- Black Glass Bottle1

- Black Laptop Bags Backpack with USB Charging1

- Black Sturdy Women's Ballet Backpack Wholesaler1

- Black and olive green patchwork waist pack1

- Black crossbody bag manufacturer1

- Black leather plaid pattern wash bag1

- Blind Motor Kit1

- Blood Pressure Monitor Case1

- Boiler Valve Control2

- Brand customization with EVA cases1

- Breathable Hiking Boots1

- Breathable Mesh Fabric1

- Breathable Polyester Jersey Fabric1

- Breathable Running Shoes1

- Breathable period panties factory direct1

- Building Management Systems1

- Built-in Lighting LED Mirrors1

- Bulk Bean Bag Manufactory1

- Bulk EVA case supplier1

- Bulk order period underwear supplier1

- Bulk seamless period panties supplier1

- Business Laptop Briefcase Bag1

- Business School Laptop Bags Backpack1

- Business Trip Lunck Cooler Backpack1

- Business laptop bag OEM1

- CMYK printing Aerosol Can1

- CP Multicam Camouflage Uniform1

- Camping Bag For Men Women1

- Canvas Adventure backpacks for college1

- Carry Bag For Thermomix TM5 TM6 TM311

- Carry out packing bags1

- Casual Hat1

- Centralized Heating Efficiency1

- Certified Lingerie OEM Factory1

- Chain women's handbag1

- Child Ballerina Knapsack for Dancing Supplier1

- Children's Lightweight Cute Travelling Bag Factory1

- China Bean Bag Manufacturer1

- China Custom Minimalist Waterproof Roll Top Backpack1

- China EVA foam case1

- China EVA hard shell case company1

- China Factory lace full figure bra1

- China Lingerie OEM Manufacturer1

- China Professional LED Mirror Supplier1

- China Vacation Packages1

- China Washable and reusable menstrual underwear1

- China backpack manufacturer1

- China eva foam case1

- China molded eva case1

- China private tour1

- China trip1

- Cigar Humidor Bags1

- Cigar Humidor Sealed Moisture1

- Classic Women’s Handbag Collection1

- Clear glass dropper bottles1

- Color Touchscreen Thermostat1

- Comfort Hiking Boots1

- Comfort and Versatility Lingerie for wholesale1

- Comfortable Bean Bag1

- Comfortable Bean Bag Chair4

- Comfortable Bean Bag Chairs1

- Comfortable Hiking Boots1

- Comfortable high-elastic sports shoes1

- Commercial Shoe Dryer for Shoe Stores1

- Commercial Shoe washing machine manufacturer1

- Commercial Shoes Drying Machine1

- Commercial Shoes Drying Machine Supplier1

- Commercial and Residential LED Mirror1

- Commercial shoe dryer2

- Commercial shoe washing machine1

- Company Logo Plastic Bags1

- Compression Molded EVA Case1

- Computer backpack manufacturs1

- Connected and Intelligent Thermostatic Head1

- Consumer Electronics EVA Case1

- Convenient front-closure bra for seniors bulk purchase1

- Cooler Bag Custom1

- Cooler Box Picnic Bag1

- Cord Roller Blinds1

- Cordless Blinds Spring Motor1

- Cosmetic Glass Bottles1

- Cosmetic Glass Pump Bottles1

- Cosmetic Tube manufacturer1

- Cosmetic packaging1

- Cosmetic products1

- Cosmetic storage bag1

- Cosmetic tube manufacturer1

- Cotton Bean Bags1

- Cotton Polyester Blend Coat1

- Cozy Bean Bag Chair1

- Cozy Bean Bag Chairs3

- Custom Ballerinas Full Printing Barrel Duffel Bag1

- Custom Bean Bag Chair3

- Custom Bean Bag Chairs2

- Custom Boot Bag1

- Custom Clothing Factory1

- Custom Coolers Fast Shipping1

- Custom Design LED Vanity Mirror1

- Custom EVA Case Manufacturer in China1

- Custom EVA Case Projects1

- Custom EVA Case Solutions1

- Custom EVA Case packaging1

- Custom EVA Cases1

- Custom EVA Cases Hardware1

- Custom EVA Cases for Drones1

- Custom EVA Foam Case Manufacturer1

- Custom EVA Hard Shell Filter Lens Case1

- Custom EVA Hard Shell Laptop Case1

- Custom EVA case2

- Custom Ethylene Vinyl Acetate cases1

- Custom Exclusive Waterproof Gym Tote Bag3

- Custom Fanny Pack Factory1

- Custom Fully Waterproof Printing Functional School Bag1

- Custom Helmet Bag1

- Custom Lifestyle Cooler Bags1

- Custom Lightweight Purple Children's Dance Backpack1

- Custom Logo Period Underwear Manufacturer1

- Custom Logo Print Hoodie1

- Custom Logo travel bag1

- Custom Made EVA Foam Case Factory1

- Custom Mesh Fabric1

- Custom Printing Aerosol Can1

- Custom Promotional Cooler Bags1

- Custom Rolling Clear Backpack1

- Custom Seamless Bra and Panty Sets Supplier1

- Custom Skincare Bottle Packaging1

- Custom Sports Shoes1

- Custom T-shirt Print1

- Custom Thermal Kindergarten Dual Insulation Food Carry Bag1

- Custom Transparent PVC School Backpack1

- Custom Tshirt Ink Design1

- Custom Ultralight Waterproof Roll Top Backpack1

- Custom Waterproof Lightweight Fitness GYM Tote Bag1

- Custom boot bag manufacturers1

- Custom branded menstrual panties for e-commerce1

- Custom designed EVA case1

- Custom fit EVA carrying case1

- Custom logo glass bottles2

- Custom logo glass dropper bottles1

- Custom logo period underwear OEM service1

- Custom molded EVA cases1

- Custom protective EVA case1

- Custom protective cases for branding1

- Custom-made Popular Hoodie1

- Customizable Insulated Twin Compartment Lunch Bag Supplier1

- Customize1

- Customize Colors Functional Camouflage Fabric1

- Customize Seamless bra and panties1

- Customize Washable Cotton Polyester Twill Workear Fabric1

- Customized Backpack for Travel1

- Customized Bean Bag Chair1

- Customized Colorful Auto lock nylon Zipper1

- Customized Custom Helmet Bag Adjustable Straps1

- Customized Dance Active Equipment Bag1

- Customized EVA Protection Case2

- Customized EVA protection case1

- Customized Eva Hard Shell Case1

- Customized Green Lightweight Waterproof Fitness Tote Bag1

- Customized Large Tactical backpack1

- Customized Lightweight Waterproof Fitness Tote Bag4

- Customized Logo For Ladies Shoulder Bag1

- Customized Logo Messenger Bag1

- Customized Lunck Backpack1

- Customized Period Underwear1

- Customized Recycled Polyester Outdoor Travelling Tote5

- Customized Yoga United Water Resistant Elephant Yoga Mat Bag1

- Customized cosmetic glass bottles1

- Customized heavy absorbency period pants without a bulky pad1

- Customs seamless nylon bra1

- Custtom High Quality Waterproof Dry Backpack1

- Cute Mini RPET Adventure Backpacks1

- DX HVAC Control1

- Dark Blue Worker Pants For Industrial Use1

- Dark Glass Bottle1

- Decor life home decor1

- Designer shoulder bags1

- Designing a Custom EVA Case1

- Detachable Radiator Thermostat with Temperature Sensor1

- Diamond printed tote bag1

- Diamond striped large shoulder bag1

- Dimmable LED Dressing Mirror1

- Dongguan EVA case factory1

- Dongguan OEM EVA Case factory1

- Dressing Mirror with Lights1

- Drill Bits For Nail Drill1

- Dry Bag Ourdoor Travel1

- Duffel Bag With Wheels1

- Duffle Travel Bag Tarpaulin1

- Durable Bean Bag Chairs1

- Durable Dual Insulation Lunch Tote Wholesale1

- Durable EVA Case for Thermometer1

- Durable EVA cases1

- Durable and Lightweight Duffel Bag1

- EPS Bean Bag Filler1

- EVA Blood Glucose Meter Case1

- EVA Case Customization 1011

- EVA Case Customization Factory1

- EVA Case Design and Manufacturing Services1

- EVA Case Durability and Quality1

- EVA Case Lab Test1

- EVA Case Manufacturing1

- EVA Case Manufacturing and Customization1

- EVA Case Reliability1

- EVA Case Solutions1

- EVA Case packaging partner1

- EVA Cases Medical Devices1

- EVA Consumer Electronics Cases1

- EVA First Aid Case1

- EVA Foam Case2

- EVA Foam Case Production Facility1

- EVA Golf Balls Case Hard Shell1

- EVA Hard Shell Laptop Case1

- EVA Headphones Case1

- EVA Insulin Storage Case1

- EVA Packaging Solutions Supplier2

- EVA Packing Solution1

- EVA Shockproof Resistant Carrying Case1

- EVA Travel Storage Box1

- EVA blood pressure monitor cases1

- EVA carrying case1

- EVA carrying case manufacturer1

- EVA case Custom Mold Tooling1

- EVA case branding1

- EVA case development1

- EVA case experts1

- EVA case for controllers1

- EVA case maintenance tips1

- EVA case manufacturer2

- EVA case packaging solutions1

- EVA case partner1

- EVA case solutions1

- EVA case sourcing1

- EVA case supplier1

- EVA case unboxing experience1

- EVA case with foam insert for safe storage1

- EVA case with zipper for compact storage2

- EVA cases factory1

- EVA consumer electronics cases1

- EVA custom carrying cases manufacturer1

- EVA custom equipment case1

- EVA foam case1

- EVA foam case China1

- EVA foam interiors custom molded1

- EVA hard shell carry case1

- EVA hard shell case1

- EVA packaging box1

- EVA pencil case1

- EVA pencil case supplier1

- EVA protective packaging1

- EVA storage packaging bag1

- EVA travel case1

- EVA zipper packaging case1

- Easy-to-wear front hook bra OEM for B2B1

- Eco Bean Bag Filling1

- Eco Friendly Bean Bag1

- Eco Friendly Bean Bag Chairs1

- Eco Friendly Bean Bag Filler1

- Eco Friendly Furniture1

- Eco friendly EVA case1

- Eco-Friendly Beauty Tubes1

- Eco-Friendly Menstrual Underwear ODM1

- Eco-Friendly Soft and Easycarry Children Lunch Bag1

- Eco-friendly Cosmetic Packaging Solutions1

- Electric Hand Mixer1

- Electric Underfloor Heating Thermostat1

- Electric Underfloor Heating Thermostats1

- Electric Underfloor Heating with a Smart Thermostat1

- Electronics EVA Case1

- Elegant Party Dress1

- Empty Aerosol Can1

- Empty Aerosol Tin Cans1

- Empty Aerosol Tinplate Cans1

- Empty aerosol cans1

- Energy Efficiency LED Mirrors for Daily Use1

- Energy Saving Thermostat1

- Eps Bean Bag Filling1

- Equestrian Breeches1

- Equestrian Clothing1

- Equestrian Show Jacket1

- Essential Oil Bottle2

- Essential oil bottle dropper1

- Essential oil bottle manufacturer1

- Ethylene Vinyl Acetate case1

- European shoulder bag market1

- Evening Event Dresses1

- Everyday Life Kindergarten School Bag1

- Expandable Capacity Duffel Bags1

- Experienced EVA case factory1

- Expert EVA Case Solutions1

- FCU Thermostat1

- Fabric Vertical Blinds1

- Factory Custom Dry Backpack1

- Factory Custom Helmet Bag1

- Factory Custom Premium Sexy Lingerie Set1

- Factory Custom Rolling Clear Backpack1

- Factory Eco - Friendly Waterproof Duffel Bag1

- Factory Empty Aerosol Can1

- Factory Outlet Thermomix Carry Bag1

- Factory Price For Waist Pack1

- Factory Price LED Bathroom Mirror1

- Factory Price for seamless thong1

- Factory Waterproof Dry Backpack1

- Factory direct sales wedding lace1

- Factory price backpack with USB Charging1

- Factory suppler Auto lock zipper1

- Factory suppler nylon auto lock zipper1

- Factory suppler tactical men jungle boot1

- Fan Coil Thermostat1

- Fashion Design LED Vanity Mirror1

- Fashion Sneakers Shoes1

- Fashion computer backpack1

- Fashion laptop backpack for women1

- Fashion laptop backpack vendors1

- Fashionable Safety Shoes with composite toecap1

- Fashionable wedding dress lace1

- Finess backpack bag fashion1

- Flexible MOQ Seamless Wireless Bra Manufacturer1

- Floating dry backpack for outdoor trips1

- Foam Bean Bag Chair1

- Food Delivery Bag1

- Food Delivery Bag Manufacturer1

- Foodsaver Bags Zipper1

- Full Face Gas Mask1

- Full QC Wireless Bra Production Supplier1

- Full coverage leakproof panties for night use1

- Full-touch Display1

- Furniture Industry Trends1

- Furniture Sofa Couch1

- GORE TEX dog wear1

- GOTS certified organic cotton period panties1

- GPPS plastic accessories1

- Garment Washed Factory1

- Garments OEM ODM1

- Genuine leather hat1

- Giant Bean Bag Chair1

- Giant Foam Bean Bag1

- Glamorous Bag For Women1

- Glass Dropper Bottles Manufacturer1

- Glass bottle for serum1

- Glass bottle for vitamin C serum1

- Gloves Synthetic Leather1

- Go Light Yoga Mat Carrier Manufacturer1

- Good Quality Bean Bag1

- Gorhia handbag1

- Gradient Clothing1

- Gradient Garment Manufacturer1

- Green Anti mould Sticker1

- Grils Colorful Dance Tote Bag Manufacturer1

- Guangdong Sihai Tin Can1

- Gym backpack with shoes compartment1

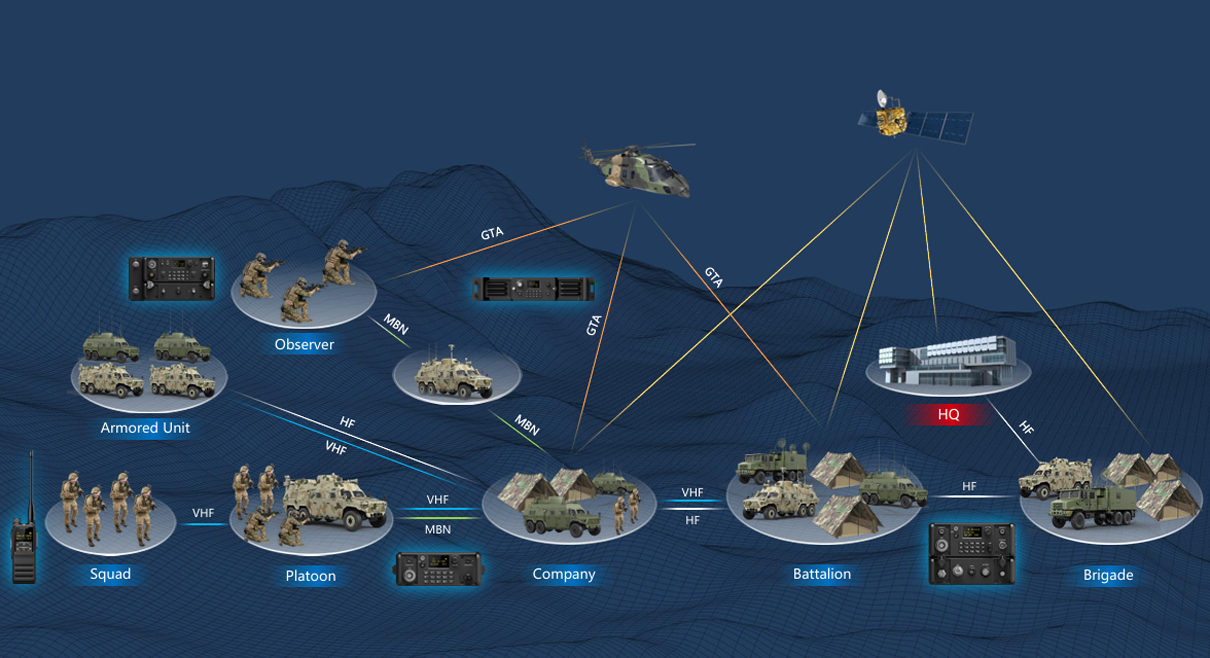

- HF radio1

- HVAC Billing Thermostat1

- HVAC thermostat1

- Hand Mixer1

- Handheld Food Delivery Bags1

- Handmade Watch Carrying Case1

- Hanging Wall Art Decor1

- Hanging wall ornament1

- Harbin Ice Festival Tours1

- Harbin Ice and Snow World1

- Harbin Travel Guide1

- Harbin travel1

- Hard EVA Carry Tool Case1

- Hard EVA Student Pencil Case1

- Hard Shell PU Tea Travel Box1

- Hard Ski EVA Box1

- Hard Watch Box Organizer1

- Heat Transfer Printing Neoprene Lunch Bag Factory1

- Heavy Duty school holographic bookbags1

- Helmet Storage Bag1

- Helmet Storage Bag black1

- High Absorbency Period Panties1

- High Density Tulle Fabric1

- High Quality Bean Bag Chair1

- High Quality Genuine Leather Jungle Boots1

- High Quality Waterproof Dry Backpack1

- High Quality Women'S Tote Bag1

- High-Quality EVA Carrying Case1

- High-end perfume glass bottle1

- High-quality Hardshell Binocular Case1

- High-quality Jersey Fabric1

- Hiking Boots1

- Home decor vintage1

- Hot Sale Men's Shoulder Bag1

- Hot Sale Messenger Bag For Men1

- Hot selling baseball caps1

- How to Wash Period Underwear?1

- How to find the underwear wholesaler1

- ISO quality system certification1

- ISO14001 Environmental Management System1

- ISO9001 EVA case supplier1

- ISO9001 Quality Management System1

- Ice Cream Dance Duffle Bag Manufacturer1

- If Period panties can replace menstrual cup?1

- Indoor Air Quality Sensors1

- Industrial Construction Shoes1

- Industrial Shoe Dryer manufacturer1

- Industrial Shoe Dryer with UV Sterilization1

- Industrial Washable Funtional Work Pants Fabric1

- Industrial shoe dryer1

- Inflatable Camping Tent1

- Inflatable Outdoor Tents1

- Inflatable tents1

- Inside Pockets Jacket1

- Insulated Food Delivery Bags1

- Insulated Hydration Camping backpack1

- Insulated Hydration Camping backpack Hiking1

- Insulated Promotional Cooler Bags1

- Insulation Lunch Bag1

- Kids Bean Bag Chairs1

- Kitchen Appliance Designer1

- LED Compact Mirror1

- LED Desktop Makeup Mirror1

- LED Handhel Makeup Mirror1

- LED Hollywood Makeup Mirror1

- LED Hollywood Mirror1

- LED Light Mirror for Bathroom1

- LED Portable Makeup Mirror1

- LED Tabletop Makeup Mirror2

- LED Vanity Mirror with Touch Button1

- LED mirror for furniture store1

- Lace-Up Wading Shoes1

- Laptop Bags Backpack with USB Charging1

- Large Reliable Dance Gear Bag for Ladies Supplier1

- Large Waterproof luggage bags1

- Large capacity sling bag1

- Large capacity travel bag1

- Laser cut panties for tight dress manufacturing1

- Laundry Equipment Shoes Dryer Machine1

- Leak-proof four layers period underwear1

- Leakproof Seamless Period Underwear Factory1

- Leather Bean Bag Chairs1

- Light Running Shoes1

- Lighted Full-Length Mirror with Bracket1

- Lighted Vanity Makeup Mirror1

- Lightest most comfortable safety shoes1

- Lightweight Bags for Swimming1

- Lightweight Bean Bag Chair1

- Lightweight Comfortable Camping Trekking Trail Shoes1

- Lightweight Daily Shool Neoprene Cooler Pack Factory1

- Lightweight EVA Storage Case1

- Lightweight EVA case1

- Lightweight Military Gas Mask1

- Lightweight Safety Shoes1

- Lightweight Safety Shoes supplier in China1

- Lightweight Tulle Fabric1

- Lightweight and Breathable Menstrual panty1

- Lightweight dry backpack outdoor excursion1

- Lingerie Manufacturing Lead Time1

- Lingerie ODM OEM Services1

- Lingerie Quality Control Manufacturer1

- Lingerie factory OEM seamless underwear1

- Lingerie manufacturer1

- Liquid Foundation Glass Bottle1

- Lisson Group1

- Litchi Festival1

- Low MOQ Camera Bag For Men1

- Low Price Leather Tote Handbags For Women1

- Low Price Women'S Handbag1

- Luggage Bags with Wheels1

- Luggage Travel Bags with Wheels1

- Luxury Cosmetic Tubes Packaging1

- Luxury EVA case1

- Luxury Glass Bottles1

- MTB riding wear customed1

- MTB riding wear factory1

- Macbook Compatible Protective Laptop Bag1

- Make up Vanity Mirror with Lights1

- Makeup Mirror with Bulbs1

- Makeup bag with mirror1

- Manufactories light tummy contorl panties1

- Manufacture UV Mosquito Teflon Resistant Camouflage Workwear Fabric1

- Manufacturer Men's Fashion Crossbody Bag1

- Manufacturer Men's fashion bag1

- Manufacturer Tote Bags For Women1

- Manufacturer Vintage Men Messenger Bag1

- Manufacturer Women'S Tote Bag2

- Manufacturer Workwear Washable Industrial Fabric1

- Material of plastic bottle1

- Medical Devices EVA Cases1

- Medical EVA Cases2

- Men's Custom Logo Handbag1

- Men's casual sports shoes1

- Mens Waterproof Suede Hiking Shoes Manufacturer1

- Mesh Fabric Factory1

- Messenger bag manufacturer1

- Messenger bags custom color1

- Metering Thermostat1

- Microfiber Leather Factory1

- Microfiber Leather Manufacturer1

- Microfiber Leather Supplier1

- Microfiber PU Suede1

- Mildew and moisture proofing company1

- Military Camo Cap1

- Military army tactical Tactical Uniforms customized logo1

- Military boots leather1

- Military communication1

- Military radio1

- Military walkie talkie1

- Mini Waterproof Roll Top Backpack Custom1

- Modbus Metering Thermostat1

- Modern Aesthetic Home Decoration Mirrors1

- Modern Bean Bag Sofa1

- Moisture Absorbable Breathable Jacket1

- Most comfortable lightweight safety shoes1

- Motorized Roller Shade Kit1

- Multi - Carry Option Duffels Bag1

- Multi functional office shoulder bag1

- NIJ Level III Plates1

- NIJ Level IV Plates1

- Nail Bits For Drill1

- Nail Bits For Nail Drill1

- Nail Drill Bits1

- Nail Drill With Bits1

- Natural Bean Bag Filling1

- Necked-in Type Empty Can1

- New Luxury Handbag1

- No Panty Line Seamless Panties For Wholesale1

- Non-slip Running Shoes1

- Non-slip Wear-resistant Outdoor Shoes For Men1

- ODM Children Double Insulated Food Carrier Factory1

- ODM EVA Case1

- ODM EVA packaging solutions1

- ODM Helmet Bag1

- ODM Laptop Bags Backpack1

- ODM Men's Windbreaker Jacket1

- ODM Polyester Cotton Hat1

- ODM Short Sleeve T-Shirt1

- ODM Tactical Sunshade Cap1

- ODM lingerie factory1

- ODM seamless underwear collection1

- OEKO-TEX underwear supplier1

- OEM & ODM Seamless patnies1

- OEM 2-pockets Tactical T-Shirt1

- OEM Baseball Male Velcro Cap1

- OEM Black Genuine Embossed Leather Jungle Boot1

- OEM Bunny Loves You Barrel School Bag1

- OEM Commuter Waterproof Roll Top Backpack1

- OEM Custom EVA Cases1

- OEM Durable Preschool Backpack for your Children1

- OEM EVA Case Factory1

- OEM EVA case factories1

- OEM EVA case manufacturer1

- OEM EVA packaging1

- OEM EVA tool cases1

- OEM Eco-Friendly Seamless Period Panties1

- OEM Factory 250GSM Industrial Functional1

- OEM Helmet Bag1

- OEM High-waist leakproof panties1

- OEM Hiking French Security Tactical Hat1

- OEM Individualized Lightweight Fitness Tote Bag4

- OEM Lace Wireless Bra Set For Plus Size Women1

- OEM Lace wireless bra for plus size women1

- OEM Lady Travelling Shoulder Weekender in Black Nylon1

- OEM Laptop Bags Backpack1

- OEM Lightweight Ballet Kit Bag1

- OEM Lingerie Supply Chain Management1

- OEM ODM Clothing1

- OEM ODM Hoodie1

- OEM ODM military Uniforms1

- OEM ODM military tactical Uniforms1

- OEM Olive Green Travel Yoga Gym Bag for Women1

- OEM Outdoor Camouflage Jacket1

- OEM Packaging Solutions1

- OEM Price1

- OEM Price Camouflage Outdoor Polyester Cotton Fabric1

- OEM RPET BottleGreen Choice Daily Neoprene Backpack Factory1

- OEM Seamless Period Pants Production1

- OEM Shockproof EVA case1

- OEM Smart Thermostat1

- OEM Streetwear1

- OEM Sustainable Period Underwear Supplier1

- OEM Tarpaulin Travel Bag1

- OEM Thermostat Supplier1

- OEM Turmeric Face Mask1

- OEM Underwear Production Timeline1

- OEM Waist Bag From China1

- OEM Washable Colorful Customized Neoprene Lunch Bag1

- OEM Waterproof Dry Backpack1

- OEM Women Gym Trainning Yoga Bag1

- OEM acrylic cosmetic containers1

- OEM and ODM Lingerie Manufacturer1

- OEM eva zipper case1

- OEM leakproof period underwear factory1

- OEM menstrual underwear factory1

- OEM period panties factory1

- OEM seamless bra and panties1

- OEM seamless bra manufacturer1

- OEM seamless menstrual underwear with low MOQ2

- OEM seamless underwear manufacturer2

- OEM shapewear factory1

- OEM& ODM High waist Thong1

- OEM& ODM Tummy Contorl Thong1

- OEM/ODM Wholesale Manufacturer Military Army Tactical Uniforms1

- OEM/ODM Wholesale Manufacturer Military Army Uniforms1

- Odor-resistant and leakproof period panties1

- Oem & Odm Mid flow period panties1

- Oem Manufacturer Of Leather Bag1

- Office & Education EVA Case1

- One stop-solution underwear manufacturer1

- One-Piece Bodysuit Shapewear OEM ODM Factory1

- Outdoor Bean Bag Chair1

- Outdoor Bean Bags1

- Outdoor Furniture High Quality1

- Outdoor Gym - going Bag1

- Outdoor Hiking Shoes1

- Outdoor Insulated Hydration Camping backpack1

- Outdoor Jacket Manufacturer1

- Outdoor Travel BackpackTarpaulin1

- Outdoor Wading Shoes1

- Outdoor camping travel dry backpack1

- Outdoor exercise and fitness bag1

- Outdoor travel dry backpack1

- Outdoor travel dry backpack Waterproof dry backpack for outdoor travel1

- Outdoor travel storage bag2

- Outdoor uniform fabric1

- Outdoor venetian blinds1

- PANWAY Cooler Bag1

- PE Anti mould Paper1

- PE Mildew proof paper1

- PET bottle for shampoo1

- PLA plastic bags1

- PP Fruit Bags1

- PU Jewelry Cases1

- PU Synthetic Leather1

- PU leather baseball cap1

- PU leather garment1

- Panway Dry Bag Waterproof1

- Panway Hydration Camping backpack1

- Perfect Custom EVA Cases1

- Perfect Lightweight Unique Printing Children Backpack Supplier1

- Performance MTB DH Riding Wear1

- Personal Logo Printed Bags1

- Personalized Coolers Bags1

- Personalized EVA case1

- Personalized EVA cases1

- Personalized Galaxy Daily Two Compartment Insulated Lunch Bag1

- Picnic Backpack With USB Charging Port1

- Plastic PVC Vertical Blinds1

- Plastic SR Buckles1

- Plastic T-Shirt Bag1

- Plastic materials1

- Pleated Blinds1

- Police Anti Riot Suit1

- Polyester Insulated Children Double Lunch Case Manufacturer1

- Polyester Jersey Fabric1

- Polyester Lace Sewing lace Trim1

- Polyester Roller Blinds1

- Polyester Toddler Midsize Kids School Backpack Manufacturer1

- Polyester Watch Cases1

- Portable Camera Storage Box1

- Portable EVA Binocular Case1

- Portable EVA Travel Case1

- Portable Hard EVA Case1

- Portable Tea Set Travel Case1

- Practitioner of Lifestyle Aesthetics1

- Precautions for Aerosol Cans1

- Premium absorbent menstrual underwear for EU market1

- Print Logo Hoodie1

- Printing of skin care product tubes1

- Private Label Comfy Seamless Period Panties1

- Private Label Lingerie Supplier1

- Private label convenient front-closure bra for seniors1

- Private label period underwear OEM1

- Private label seamless panties factory1

- Private-Label Comfort And High Quality Period Underwear1

- Private-label laser-cut seamless panties supplier1

- Private-label seamless bra bulk order1

- Professional Table Tennis Shoes1

- Professional laptop bag branded1

- Quality Bean Bag Chair1

- Quality Bean Bag Chairs3

- Quality Outdoor Furniture1

- Quick Side Release Buckle2

- RH 62% herbs Humidor1

- RS485 Thermostat1

- Recyclable children school bag Custom1

- Recycled Athletic Wear1

- Recycled Breathe Easy Yoga Bag Factory1

- Red Microfiber Suede1

- Refillable Glass Containers1

- Reliable Custom EVA Case Vendor1

- Reliable EVA Case OEM Factory1

- Reliable EVA Case Supplier1

- Reusable Cosmetic Bottles1

- Reusable Period Underwear Wholesale1

- Reuse Glass Dropper Bottles1

- Roll top dry backpack for outdoor adventures1

- Roller Blinds1

- Roller Blinds Motor For Sale1

- Roller Blinds Motor Kit1

- Roller Tote Soft Trolley Cooler Bags1

- Round Bean Bag Chair1

- Rubber Outsole Combat Tactical Men/Women Jungle Boots1

- Running Insulated Hydration Camping backpack1

- SEA8891

- SLEEPING BAGS1

- Sanya tour guide1

- School Backpack With USB Charging Port1

- Sealed Plastic Cigar Humidor1

- Sealed cigar humidor1

- Seamless Lingerie Manufacturing1

- Seamless Lingerie OEM Manufacturing1

- Seamless front-closure bra for seniors wholesale1

- Seamless underwear for wholesale1

- Seampless panties for wholesale1

- Self Adhesive Packing Bags For Bread1

- Semi-automatic shoe washing machine1

- Sensors of Baby Clothes1

- Shanghai China tour packages1

- Shanghai Disney Resort Travel1

- Shanghai Private Tour Packages1

- Shanghai Tours Guide1

- Shanghai Travel Agency1

- Shanghai Travel Guide1

- Shaped Bean Bag Chairs1

- Shiny Nylon Fitness Easy Carry Bag Supplier1

- Shockproof EVA Carrying Case1

- Shockproof Gaming Laptop Bag1

- Shoe dryer1

- Shoe dryer manufacturer1

- Shoe drying equipment1

- Shoe washing and drying machine1

- Shoe washing machine for shoe shop1

- Shoe washing machine supplier1

- Shoes dryer with sterilization function2

- Shopping bag classic printed women's bag1

- Shoulder bag Europe1

- Side Release Buckle1

- Side Release Buckles1

- Skin care glass bottles1

- Skin care tube1

- Skincare Cosmetic Glass Bottle1

- Sling bag fashion style1

- Small Portable Jewelry Organizer Case1

- Smart Baby Clothes1

- Smart Electric Underfloor Heating Thermostat1

- Smart Electric Underfloor Heating Thermostats1

- Smart HVAC Upgrade1

- Smart Radiator Valve1

- Smart Radiator Valves2

- Smart TRV1

- Smart Thermostat2

- Smart Thermostat for Radiant Heating1

- Smart Zigbee 3.0 Radiator Thermostat1

- Sofa Suede Leatherette1

- Soft Full Printing Lightweight Sustainable Neoprene Lunch Bag1

- Solid color diamond patterned jewelry box1

- Source Custom High Quality Lingerie Factory1

- Sports Insulated Hydration Camping backpack1

- Sports bag suppliers1

- Sports period panties wholesale supplier1

- Spray cans3

- Spring Loaded Motor For Cordless Shades1

- Square Bean Bag Chair1

- Square Bottle With Push dropper1

- Square makeup bag1

- Square pink bag1

- St. Sophia Cathedral1

- Stable Hiking Boots1

- Step by Step EVA Case Customization1

- Streetwear Manufacturer1

- Stylish Bean Bag Chairs1

- Stylish shoulder bags1

- Sublimation Lightweight Neoprene Kids Lunch Bags Custom1

- Suede Leatherette Fabric1

- Summer Breathable T-Shirt1

- Super Fine Soft Tulle Fabric1

- Super leakproof menstrual brief for wholesale1

- Supermarket shopping bags1

- Supplier Custom Printed Logo Tote Bags1

- Supply Durable Fitness Duffle Sport Shopper1

- Supply Durable Unique Sport Shopper4

- Supply GYM Fitness Sporty Shoulder Bag1

- Supply Reusable colorful students Bag1

- Supply Safe and Sustainable Kids Backpack1

- Supply Sublimation School Shoulder Bag Travel Bag1

- Supply Throwback Triple-Zip Duffle Tote Bag1

- Supply Yoga Design Lab Mat Bag1

- Supply shoe dryer2

- Supportive Bean Bag Chair1

- Sustainability and Eco-Friendly underwear1

- Sustainable Bean Bag Filling1

- Sustainable Lightweight Kids Backpack supplier1

- Sustainable period panties for B2B buyers1

- Sustainable school backpack Manufacturer1

- T Shirt Design1

- T Shirt Maker1

- T/C 65% Polyester 35% Cotton T-Shirt1

- TRV Thermostatic Radiator1

- TRV Wireless Thermostatic Valve1

- TRV radiator thermostat1

- Table Tennis Training Shoes1

- Tactical Anti Riot Suit1

- Tactical Helmet Bag1

- Tactical Helmet Bag outdoor1

- Tactical Uniforms wholesale price1

- Tactical backpack Factory Price1

- Tactical backpack for Hiking1

- Tactical backpack for Hunting1

- Tactical backpack for Sports1

- Tactical backpack waterproof1

- Tailored EVA Case Solutions1

- Tarpaulin Duffle Bag Factory Price1

- Tarpaulin Duffle Travel Bag1

- Tarpaulin Duffle Travel Bag Wholesale1

- The Best Insulated Cooler Bags of 20241

- The Forbidden City Tour1

- The Thermomix Travel Carry Bag1

- Thermoform EVA Cases1

- Thermomix Bag Appliance Cooker Home1

- Thermomix Carry Bag Custom Logo1

- Thermostat Valve1

- Thermostat manufacturers1

- Things to do in China1

- Three Velcro Male Patch Cap1

- Tinplate Aerosol Can1

- Tinplate Can1

- Tinplate Cans1

- Tinplate aerosol cans1

- Toddler Dance Backpack School Bag Supplier1

- Touchscreen Thermostat2

- Tourism Cooler Backpack1

- Transparent Double Layer Cigar Box1

- Transparent PVC backpack Bag with Wheels1

- Travel Backpack With USB Charging Port1

- Travel Bags with Wheels1

- Travel Size Cosmetic Tubes1

- Travel Tool Carry Bag Thermomix1

- Travel backpack custom color1

- Travel from Swiss to China1

- Travel in Beijing1

- Travel laptop backpack suppliers1

- Travel storage box with dividers1

- Travel to China3

- Treadmill Belt Replacement1

- Trekking Camping Outdoor Shoes1

- Trendy sporty safety shoes in China1

- Trolley Cooler Bag Custom Logo1

- Trolley Cooler Bag Factory Price1

- Trolley Cooler Bag Wholesale1

- Turmeric Kojic Acid Serum custom1

- Tuya Thermostatic Head1

- UV protection cosmetic bottle1

- UV protection glass bottle1

- UV-protective cosmetic packaging1

- UV-protective glass bottles1

- Ultra comfy seamless bras1

- Underfloor Heating Controller1

- Unique shoulder bag trends in Europe1

- Unisex Lightweight Laptop Shoulder Bag1

- User-centered design1

- VHF radio1

- Vanity Makeup Mirror Desk1

- Vanity Mirror with Led Lights1

- Vanity Mirror with Lights1

- Vanity Mirror with Lights for Bedroom1

- Velvet Bean Bag Chairs1

- Venetian blinds1

- Vintage Brown Tote Bag,Woman Bag Factory,Women's Elegant Handbag1

- WIFI Thermostatic Radiator Valve1

- WW2 German police cotton Tunic1

- WW2 german Helmet1

- WW2 german police uniforms1

- WW2 german uniforms1

- WW2 helmet1

- WW2 militaria1

- WWII German Wool Tunic1

- WWII german militaria1

- WWII german police militaria1

- WWII police uniform1

- Waist Pack Bag for Men1

- Waist Pack Bag for Women1

- Wall WPC Cladding1

- Wall-mounted LED Standing Floor Mirror1

- Washing Shop Commercial Shoe Dryer1

- Water Underfloor Heating Systems1

- Water Underfloor Heating Thermostat3

- Water-Resistant Breathable Hiking Shoes1

- Water-resistant Breathable Suede Hiking Boots1

- Waterproof Bags Backpacks Lightweight1

- Waterproof Bean Bag Chair1

- Waterproof Cooler Bag1

- Waterproof Dancer's Gear Duffle Factory1

- Waterproof Dry Backpack1

- Waterproof Dry Backpack wholesale1

- Waterproof Dry Bags for Camping1

- Waterproof EVA Cases1

- Waterproof Goretex Outer Wear1

- Waterproof Insulation Pack Cooler Bag1

- Waterproof Large Size B2S Book Backpack1

- Waterproof Material Gym Bag1

- Waterproof Medical Cases1

- Waterproof Outdoor Bean Bags1

- Waterproof Polyester Pink Sport Accessory Bag1

- Waterproof black PU crossbody bag1

- Waterproof lightweight Daily PU Leather Backpack Manufacturer1

- Waterproof travel bag1

- Wet Wading Shoes1

- What is the difference between seamless underwear & regular1

- White label activewear underwear1

- Wholesale1

- Wholesale Anti Infrared Camouflage Outdoor Fabric1

- Wholesale Bean Bag Chairs1

- Wholesale Bonnie Outdoor Tactical Hat1

- Wholesale Clothing Custom1

- Wholesale Custom Boot Bag1

- Wholesale EVA case supplier1

- Wholesale Fanny Pack1

- Wholesale Helmet Bag Factory Price1

- Wholesale LED Home Decor Mirror1

- Wholesale Lingerie Factory China1

- Wholesale Men Luxury Messenger Bags1

- Wholesale Military Tactical Jacket1

- Wholesale Military Tactical T-Shirt1

- Wholesale ODM Seamless Wireless Bra1

- Wholesale Outdoor Sports Cap1

- Wholesale PVC backpack Bag with Wheels1

- Wholesale Period panties with leakproof1

- Wholesale Price Anti-slip Men Jungle Boots1

- Wholesale Price Cotton Polyester Spandex Workwear Twill Fabric1

- Wholesale Price Men's Shoulder Bag1

- Wholesale Suppliers For Handbags2

- Wholesale Women's Shoulder Bags1

- Wholesale YKK resin zip black EVA antibacterial outsole jungle boot1

- Wholesale best fitting panty for womens underwear1

- Wholesale plus-size seamless bra manufacturer1

- Wholesale seamless bra and panties1

- Wholesale seamless panties supplier1

- Wholesale skims shapewear1

- Wholesale supportive bralette1

- Why choose seamless panties for workout1

- Wi-Fi Floor Heating Thermostat1

- WiFi Smart TRV1

- Wifi Thermostatic Radiator1

- Wifi garden hose timers1

- Wireless Thermostatic Radiator Valve1

- Wireless bras for wholesale1

- Woman Bag Factory1

- Woman Bag Factory,Custom Handbag Manufacturer1

- Women's Sport Large Tote Fitness Bag Wholesale1

- Women's Underwear Wholesale1

- Women's glossy leather crossbody bag1

- Woodland Camo Short-sleeve Mounted T-Shirt1

- Workplace Footwear Trends1

- Xi'an Private Package Tour1

- Xi'an Tour Packages1

- Xi'an Travel Agency1

- Xi'an Travel Guide1

- Xiamen tour packages1

- Yisi eva cases packing1

- Yoga luxury bag manufacture1

- Youth Lightweight Petite Ballet Bag Factory1

- ZIGBEE Smart Sprinkler Timer1

- Zipper Travel Cases 1

- Zipper Travel Watch Cases 1

- a commuter backpack for outdoor1

- a duffel bag with padded straps1

- abrasion resistant camouflage fabrics1

- acrylic makeup organizer1

- adventure backpack supplier1

- adventure backpacks OEM1

- aerosol can printing1

- aerosol tin can2

- aerosol tin cans1

- airless lotion pump bottle factory1

- airless pump bottles1

- airless pump bottles manufacturer1

- airless pump glass bottle1

- airless pump plastic bottle1

- aluminum cosmetic tube1

- aluminum tube manufacturing1

- amber cosmetic packaging1

- anti- fog led bathroom mirror1

- anti-mildew products1

- anti-mold and moisture-proof solutions1

- anti-mold paper1

- antimicrobial odor-resistant period panties1

- arch shape led bathroom mirror1

- backpack with custom printing1

- backpacks with custom printing1

- baseball cap1

- bathroom mirror led2

- bathroom round led mirror1

- bathroom vanity led mirror1

- bean bag4

- bean bag beans buy1

- bean bag beans online1

- bean bag best1

- bean bag ergonomics1

- bean bags are us1

- bed dog1

- bed pet1

- belts suppliers1

- bespoke EVA case1

- best EVA case factory in China1

- best audio eva case custom1

- best bean bag1

- best bras with removable pads1

- best diabetic shoes1

- best padded bralette1

- best quality eva hard shell case1

- best smart hose timer2

- best travel duffel bag1

- biodegradable drawstring trash bags1

- biodegradable drink bags1

- black fishing tackle bags1

- black garbage bags1

- black hat1

- black leather backpack odm1

- body-inclusive seamless shapewear manufacturer China1

- boot dryer shoe dryer1

- bottle set skincare1

- bralette with support1

- brand identity1

- brand promotion1

- breathable period panties manufacturer1

- bulk T-shirt bags1

- bulk leakproof underwear for brands1

- bulletproof hoodie canada1

- bulletproof hoodie jacket1

- camouflage fabrics supplier1

- carhartt bulletproof hoodie1

- casual sports shoes for Athletes1

- certified GRS recycled fabric underwear supplier1

- certified seamless lingerie supplier1

- cheap plastic bag1

- cheap price backpack manufacturer1

- cheap price ladies bag supplier1

- chest bag exporters1

- chest bag manufacturer1

- chest bag with black full print1

- china map1

- china military boots1

- china supplier led bathroom mirror1

- china tour1

- chinese culture1

- christmas merry1

- cigar moisturizing bag1

- clean a dog bed1

- clear bag plastic2

- clear bags company1

- cloth mildew proof paper1

- clothing anti-mold paper1

- coffee plastic bag1

- colored glass bottles1

- combat boots1

- comfort and freshness materials for period underwear1

- comfortable menstrual care solution1

- comfortable womens underwear china1

- commercial large shoe dryer1

- compact LED mirror1

- company plastic1

- consumer electronics EVA box1

- consumer electronics EVA storage cases1

- cooking routines1

- cosmetic airless bottle1

- cosmetic airless plastic bottle1

- cosmetic bottle set1

- cosmetic glass bottles1

- cosmetic glass jar1

- cosmetic jars and bottle glass1

- cosmetic packaging custom1

- cosmetic storage solutions1

- cosmetic tube packaging1

- cowhide leather boots1

- cream lotion glass bottle1

- crystal cream glass jar1

- crystal jar with lid1

- custom Aerosol Cans1

- custom EVA carry case1

- custom EVA case2

- custom EVA case design2

- custom EVA case durability1

- custom EVA case factory1

- custom EVA case manufacturer1

- custom EVA case packaging factory1

- custom EVA case solutions1

- custom EVA case tooling1

- custom EVA case vendor1

- custom EVA case with logo1

- custom EVA cases1

- custom EVA hard shell case1

- custom EVA packaging solutions5

- custom EVA pouches1

- custom EVA protective case1

- custom OEM eva case supplier1

- custom PET shampoo bottle1

- custom acrylic product manufacturers1

- custom aluminum tube1

- custom brand packaging1

- custom color airless bottle1

- custom color cosmetic packaging1

- custom colored glass bottle1

- custom colored glass bottles2

- custom colored tube1

- custom cosmetic airless jar1

- custom cosmetic glass bottle1

- custom cosmetic glass bottles1

- custom cosmetic packaging1

- custom cosmetic plastic tube1

- custom cosmetic tube1

- custom display hooks1

- custom eco-friendly airless bottle1

- custom eva audio storage bag1

- custom eva carrying case1

- custom eva case design1

- custom eva cases supplier1

- custom glucometer packaging1

- custom hard shell case1

- custom headphone eva case1

- custom hiking backpack Suppliers1

- custom large eva case1

- custom light Trekking Backpacks Outdoor1

- custom lingerie manufacturer China1

- custom logo bathroom mirror1

- custom logo eva hard case1

- custom logo perfume bottle1

- custom made EVA case mold1

- custom makeup tray1

- custom outdoor water-resistant sport backpack1

- custom perfume glass bottle1

- custom period underwear1

- custom period underwear supplier1

- custom plastic bags1

- custom plastic shopping bags1

- custom printed plastic T-shirt bags1

- custom printed ziplock bags1

- custom pro audio and video case manufacturer1

- custom seamless bra manufacturer1

- custom seamless underwear1

- custom skincare glass bottle1

- custom solutions eva box1

- custom square bottle1

- custom travel bags wholesalers1

- custom underwear manufacturer for brands1

- custom wire-free bras for wholesale1

- customed dog wear1

- customised EVA box1

- customizable fit and design eva shell cases1

- customizable leak-proof underwear1

- customizable medical device cases1

- customizable packaging1

- customization eva case interior insert1

- customized EVA cases partner1

- customized bralettes for women1

- customized shapewear supplier1

- customized shaping bodysuits supplier1

- customized underwear China1

- customized valentines underwear1

- cute vanity accessories1

- cycling hydration vest manufacturer1

- cycling wear customed1

- dactory price led bathroom mirror1

- degradable packaging materials1

- desert boots1

- desktop makeu mirror1

- diabetic foot shoes1

- diabetic house shoes1

- diabetic mens shoes1

- diabetic patients shoes1

- diameter 52mm can1

- disposable1

- distributor Plus size wireless bra with support1

- dog bed1

- dog bed bed1

- dog clothing factory1

- dog wear manufacturer1

- drawstring trash bags1

- dryer machine commercial1

- dryer machine commercial for shoes1

- durable heat formed eva case1

- durable travel bag handbag messenger bag1

- dust and water resistance eva cases1

- eTEV1

- eco conscious1

- eco friendly custom cases1

- eco-friendly fabric for period panties1

- eco-friendly foldable backpack1

- eco-friendly menstrual underwear factory1

- eco-friendly period underwear1

- eco-friendly plastic packing bags1

- eco-friendly shampoo packaging1

- eco-friendly shapewear ODM solutions for global brands1

- elegant perfume glass bottle1

- empty aerosol tin can1

- empty aerosol tin cans1

- empty essential oil glass bottle2

- empty tin can1

- endura race wear brand supplier1

- energy-effecient kitchen machine1

- engineer an EVA case1

- environmental garbage bags1

- environmentally friendly EVA cases1

- environmentally friendly glass bottles1

- environmentally friendly packaging1

- environmentally-conscious segment1

- ergonomic padded shoulder strap backpacks1

- ergonomics seating1

- essential oil bottles bulk1

- eva case development1

- eva case manufacturer1

- eva case manufacturing1

- eva case packaging1

- eva cases packaging partner1

- eva custom cases headphones1

- eva hard shell case supplier1

- eva headphone bag case1

- eva molded case1

- eva packaging case1

- eva protective carrying case1

- eva storage case factory1

- eva zipper carrying case factory1

- exclusive Turmeric Skincare Set wholesale1

- existing EVA case mold1

- experienced EVA case solution provider1

- extra large vanity mirror with lights1

- eye catching packaging1

- factoryaomeidress1

- fan coil thermostat1

- fashion design led bathroom mirror1

- first layer boots1

- fishing bags1

- fishing sling bags1

- fishing tackle bags1

- floor big mirror1

- floor mirror big1

- foam pump bottle1

- foldable backpack for travel1

- foldable backpack lightweight1

- foldable backpack with USB port1

- food bags1

- food chopper machine1

- food delivery backpack1

- food packaging and packaging design1

- food service bags1

- frosted glass skincare bottles1

- full collection lingerie OEM1

- fully customized EVA case1

- fully customized EVA cases1

- functional design eva case1

- functional tools case1

- garbage bags with drawstring1

- garbage carry bags1

- german military clothing1

- glass airless bottle1

- glass bottle packaging2

- glass bottle set1

- glass bottle set supplier1

- glass bottles1

- glass cosmetic bottle set1

- glass cosmetic packaging1

- glass serum bottle clear bottle1

- global packaging market1

- good design1

- good protective eva thermoformed cases1

- grofia messenger bag1

- hanging bag moisture absorber1

- hanging dehumidifier bag1

- hanging moisture absorber for wardrobe1

- hanging wardrobe dehumidifier1

- harbin attractions1

- harbin ice and snow festival1

- harbin ice festival1

- harbin private tour2

- harbin things to do1

- hard custom oem eva boxes1

- hard shell packaging box1

- hardware tools EVA box1

- helmet bag military1

- helmet bag sports1

- high durability thermoformed eva case1

- high quality Custom EVA cases1

- high quality EVA cases1

- high quality carrying case1

- high quality cigar humidor cigar box1

- high quality cotton fabrics1

- high quality eva cases1

- high quality eva thermoformed case1

- high quality thermoforming eva case1

- high-absorbency period underwear OEM1

- high-quality camouflage fabrics1

- hiking backpack Manufacturers1

- hot sale Crossbody bag for men1

- hot sale Crossbody bag for women1

- hot sale girls school bag1

- hot sale leather travel duffle bag1

- hot sale makeup bag for women1

- hot sale men's chest bag supplier1

- household trash bags1

- how to travel in china1

- huawin anti-mildew products1

- humidity control humidifier gel pack1

- humidor box for cigars1

- hydration backpck manufacturer1

- hydration running vests manufacturer1

- hydration vest running manufacturer1

- i Memory Trip1

- ice and snow world1

- industrial shoe washing machine1

- inexpensive plastic bags1

- innovative eva case solution1

- insulated food delivery bags1

- jewelry display fixtures1

- kitchen appliances1

- kitchen chopper machine1

- kitchen machine2

- ladies bra manufacturer1

- laptop-compatible backpack1

- large capacity foldable backpack1

- large industrial bags1

- large-volume glass bottle1

- latest airless pump bottle1

- layered belts1

- leakproof cosmetic bottle1

- leakproof menstrual underwear bulk supplier1

- leather boots1

- leather plaid pattern makeup bag1

- leather wash bag supplier1

- led bathroom mirror with backlit1

- led bathroom mirror with bluetooth speaker1

- led light makeup mirror1

- led light mirror1

- led lights mirror1

- led makeup mirror2

- led mirror1

- led mirror bathroom1

- led mirror for vanity1

- led mirror lighting1

- led wall-mounted bathroom mirror1

- less protective plastic molded cases1

- light shapewear OEM factory for private labels1

- light weight running vest manufacturer1

- lightweight and durable eva cases1

- lightweight and portable eva cases1

- lightweight eva case1

- lightweight eva travel cases1

- lightweight glass bottles1

- lightweight t shirt1

- lingerie development for brands1

- lingerie distributor1

- lingerie factory with fast lead time1

- lingerie manufacturer3

- living room ideas small spaces1

- living room layout ideas1

- living room small spaces1

- living room sofa1

- lldpe Plastic Bags2

- long plastic bag1

- longline bralette wholesale1

- lotion bottle packaging1

- lotion pump glass bottle1

- luggage bags travel manufacturer1

- luxury airless plastic bottle1

- luxury cosmetic packaging1

- luxury handbag manufacturer in China1

- luxury perfume glass bottle1

- makeup bag with led mirror1

- makeup mirror led1

- manpack radio1

- manufactories Tummy Contorl Thong1

- manufacturer padded full coverage seamless bra1

- massive floor mirror1

- meat grinder1

- medical EVA boxes1

- medical instrument EVA case1

- men's handbag manufacturer1

- men's leather chest bag factory1

- mens leather travel bags1

- merino outdoor wear1

- merry christmas merry christmas1

- messenger bag traveling bag1

- mildew and moisture-proof product1

- mildew and moisture-proof solutions2

- military Uniforms wholesale manufacturer1

- military army Uniforms customized logo1

- military black boots1

- military boots1

- mineral container desiccant1

- mirror led1

- mirror on floor1

- mirror with wireless charger1

- mirror with wireless charging1

- moisture absorbing hanging bags1

- moisture proof and mold proof products1

- moisture-wicking microfiber panties OEM1

- molded EVA case1

- molded shell cases1

- moncler puffer jacket factory1

- multi-compartment laptop carry-on backpack1

- multi-compartment laptop travel backpacks1

- multi-pocket backpack1

- neoprene lunch bags1

- nice quality eva forming case1

- non toxic EVA cases1

- odm black leather backpack from manufacturer1

- odm leather backpack computer bag from china factory1

- oem bag manufacturer2

- oem belts1

- oem engineering services1

- oem manufacturer of leather bag2

- opaque plastic bag1

- optical EVA case2

- organized backpack with compartments for travel1

- outdoor large travel backpack1

- outdoor messenger fashion OEM1

- outdoor seam taped waterproof jacket1

- outdoor wear manufacturer1

- packaging1

- packaging and food1

- packaging market growth1

- packaging protective sleeves1

- packing bags factory1

- packing bags plastic1

- pbat bags1

- perfect eva hard shell case1

- period leakproof underwear OEM1

- period underwear manufacturer1

- personalized eva foam case1

- pet bed1

- pla1

- plastic bag1

- plastic bag catalog1

- plastic bag cigar humidor1

- plastic bag dealer1

- plastic bag factory1

- plastic bag factory for sale1

- plastic bag industry1

- plastic bag plastic1

- plastic bag storage bag1

- plastic bags2

- plastic bags factory1

- plastic bags introduction1

- plastic bags manufacturer1

- plastic bags price1

- plastic bags with ziplock1

- plastic carrier bags with company logo1

- plastic drink bags with handles1

- plastic packaging supplier1

- plastic packing bags custom1

- plastic paper bags1

- plastic pe bag1

- plastic plastic bag1

- plastic plastic bag holder2

- plastic plastic bags1

- plastic shopping bags1

- plastic t shirt bags1

- plastic t-shirt bags1

- plastic trash bags1

- plastic tshirt bags wholesale1

- plasto garbage bags1

- polar fleece jacket1

- polyprop bags1

- popular style LED mirror1

- portable EVA case1

- portable EVA hard shell storage case1

- portable drink bags1

- portable hard EVA case1

- portable monocular carrying case1

- portable travel makeup mirror1

- postpartum period underwear1

- powerful marketing tools1

- precision cutting techniques EVA insert1

- premium acrylic cosmetic displays1

- premium dog apparel1

- printed plastic bags manufacturer1

- printing of glass bottles1

- private label lingerie factory1

- private label seamless bras1

- private label seamless panties1

- produce tailored lingerie efficiently1

- product catalog brochure1

- product life cycle1

- professional Custom EVA Cases1

- professional packaging solutions1

- protective carrying cases1

- puffer jacket supplier1

- pump spray bottle1

- pure cotton fabrics1

- quality craftsmanship EVA case1

- quality custom EVA case solution1

- quiet, and easy to use1

- ready-to-customize seamless lingerie1

- rechargeable mirror1

- recyclable airless bottle1

- recycled active wear OEM1

- recycled fleece pullovers1

- recycling garbage bags1

- reliable EVA case factory1

- reliable EVA case packaging solution1

- reliable customize EVA case supplier1

- retail display hooks1

- retail plastic bags1

- reusable and eco friendly hard shell eva case1

- reusable bags plastic2

- rigid eva hard shell case1

- running hydration vest manufacturer1

- seamless bamboo panties wholesale supplier1

- seamless bra and panties1

- seamless lingerie manufacturer1

- seamless lingerie set manufacturer with bonding technology1

- seamless lingerie wholesale supplier1

- seamless quick dry underwear suppliers1

- seamless thong no show underwear women1

- seamless underwear OEM supplier1

- seamless underwear manufacturer1

- seamless underwear suppliers1

- seating ergonomics1

- sencond layer cowhide1

- serum spray glass bottle1

- shampoo glass bottle1

- shock absorption EVA foam1

- shock absorption cases1

- shock absorption eva shell case1

- shoe cleaning equipment1

- shoe dryer Australia1

- shoe drying machine1

- shoe washing machine1

- shoes anti-mold paper1

- short trip duffel bag for weekends1

- silk garment1

- skin care glass bottle2

- skincare airless bottle1

- skincare bottle customized1

- skincare cosmetic glass bottle1

- skincare glass bottle set1

- skincare lotion pump glass bottle1

- skincare packaging manufacturer1

- skincare packaging supplier2

- slatwall accessories1

- slatwall display accessories1

- sling bag custom color1

- small kitchen appliance1

- small kitchen market1

- small living room layout ideas1

- small size portable crossbody bag1

- smart TRV1

- smart fan coil thermostat1

- smart garden hose timer3

- smart hose timer2

- smart thermostat1

- sofa living room1

- spray pump glass bottle1

- square frosted glass bottle1

- ss helmet cover1

- standing mirror stand1

- standing mirror with stand1

- strapless bra plus manufacturer1

- strong eva case1

- superior eva case solution1

- superior protection thermoformed eva cases1

- supermarket plastic packing bags1

- sustainability1

- sustainable outdoor wear1

- sustainable packaging solutions1

- sustainable tech wear1

- tackle bags1

- tackle bags manufacturer1

- tackle bags supplier1

- tackle bags vendors1

- tactical boots1

- tailored packaging solutions1

- takeaway and delivery1

- takeaway utensils1

- technical puffer jacket1

- the bean bag1

- the best bean bag chair1

- the forbidden city1

- thermal insulation eva cases1

- thermal insulation hard eva case1

- things to do in Beijing1

- tips for travelling china1

- travel backpack capacity by trip type1

- travel led makeup mirror1

- treadmill running belts1

- treadmill walking belts1

- trusted EVA case manufacturer1

- tuya Radiator Thermostat1

- two way humidity control1

- ultimate bean bags1

- ultra thin laser cut underwear supplier1

- underwear manufacturer1

- unique cosmetic bottle designs1

- unique glass cream jar1

- unique perfume glass bottle1

- vanity led mirror1

- vanity mirror with lights hollywood makeup1

- vanity with big mirror1

- vegetable packing bags1

- versatility hard shell eva case1

- wardrobe condensation bags1

- wash bag manufacturer1

- water hose timer wifi2

- water resistance EVA Cases1

- water resistant eva cases1

- water timer for hose wifi1

- waterproof TPU nylon travel backpacks1

- waterproof black Fishing tackle bag1

- waterproof black fishing sling pack1

- waterproof dog jacket1

- waterproof duffel bag for outdoor1

- waterproof foldable backpack1

- waterproof packing bags1

- wehrmacht Helmet1

- well designed case1

- white vanity mirror with lights1

- white vanity with mirror1

- wholesale canvas bag1

- wholesale garbage bags1

- wholesale leather makeup bag1

- wholesale lingerie suppliers1

- wholesale luxury bag for ladies1

- wholesale overnight period underwear1

- wholesale plastic bags3

- wholesale push up bralette1

- winter light high-tech puffer jacket1

- winter lightweight insulation jacket1

- wireless best push up bra1

- wireless charging mirror1

- wireless front closure bra1

- wireless second skin bra manufacturer1

- woman bag factory1

- women handbags manufacturer1

- women's backpack manufacturer1

- women's backpack supplier1

- women's diabetic shoes1

- ww2 German police summer uniforms1

- ww2 german police jacket1

- yellow outdoor canvas Adventure backpacks1

- yellow travel adventure backpack for college1

- ziplock packing bags for food1

- zipper bags1